News

news center

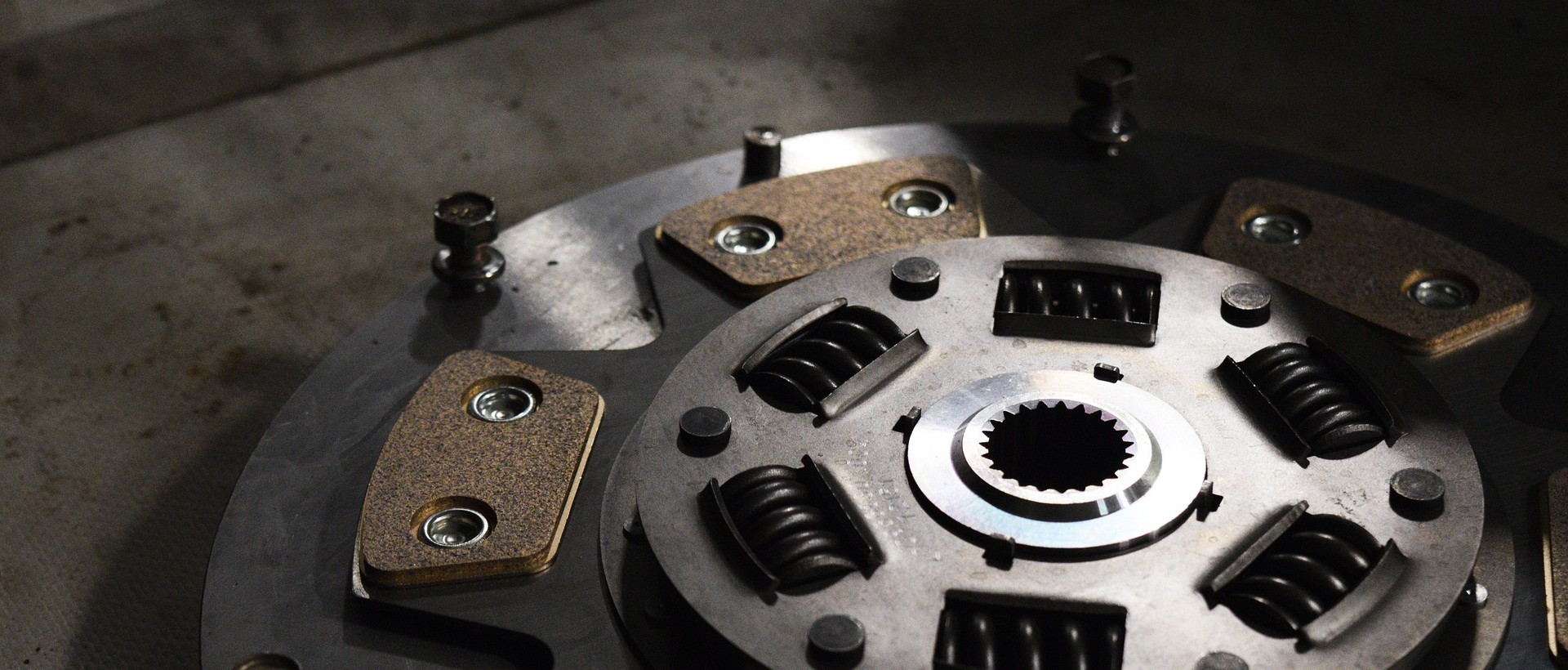

Cleaning Process and Key Points of Gear Shaft

Release time:

2023-08-26

There are many manufacturers who make shafts, and the structure of shaft parts is relatively simple. General drive shafts can be cleaned by high temperature and high pressure cleaning; for gear shaft parts, you can also clean the tooth surface. Method, metal parts should use oil cleaning agent as the cleaning medium.

Due to the complex structure of many shaft parts, the pollution of surface oil is also more serious, so according to the actual degree of pollution, choose the corresponding cleaning process or use a combination of cleaning methods. Low-foam surface degreasing agent is a cleaning agent favored by many manufacturers. Among most gear shaft parts, the cleaning process generally adopts high temperature and high pressure cleaning process. However, for parts such as variable speed shell and drive axle shell with more rust spots on the surface and old paint box shell, high temperature decomposition method can be used to clean them first, and then sandblasting or high pressure water jet process can be used to remove grease and dirt after decomposition, if necessary, it can be supplemented by oscillation process to improve the surface cleaning efficiency and cleanliness of the workpiece, and can be cleaned with oil stain cleaning agent for metal parts.

For the sun gear, bevel gear and other gear parts structure is complex, the surface form is various, in many precision workpieces, the cleanliness requirements are high, manufacturing is also very difficult, therefore, when cleaning such parts, pay attention to protect the tooth surface, avoid secondary damage, increase the difficulty of remanufacturing repair. So far, the cleaning of such parts is generally based on the ultrasonic cleaning process plus artificial scrubbing. In order to reduce the number of cleaning and protection of components, metal parts cleaning agent should be selected.

Hot News