News

news center

Electromagnetic brake how to judge good or bad, electromagnetic brake fault analysis

Release time:

2023-08-26

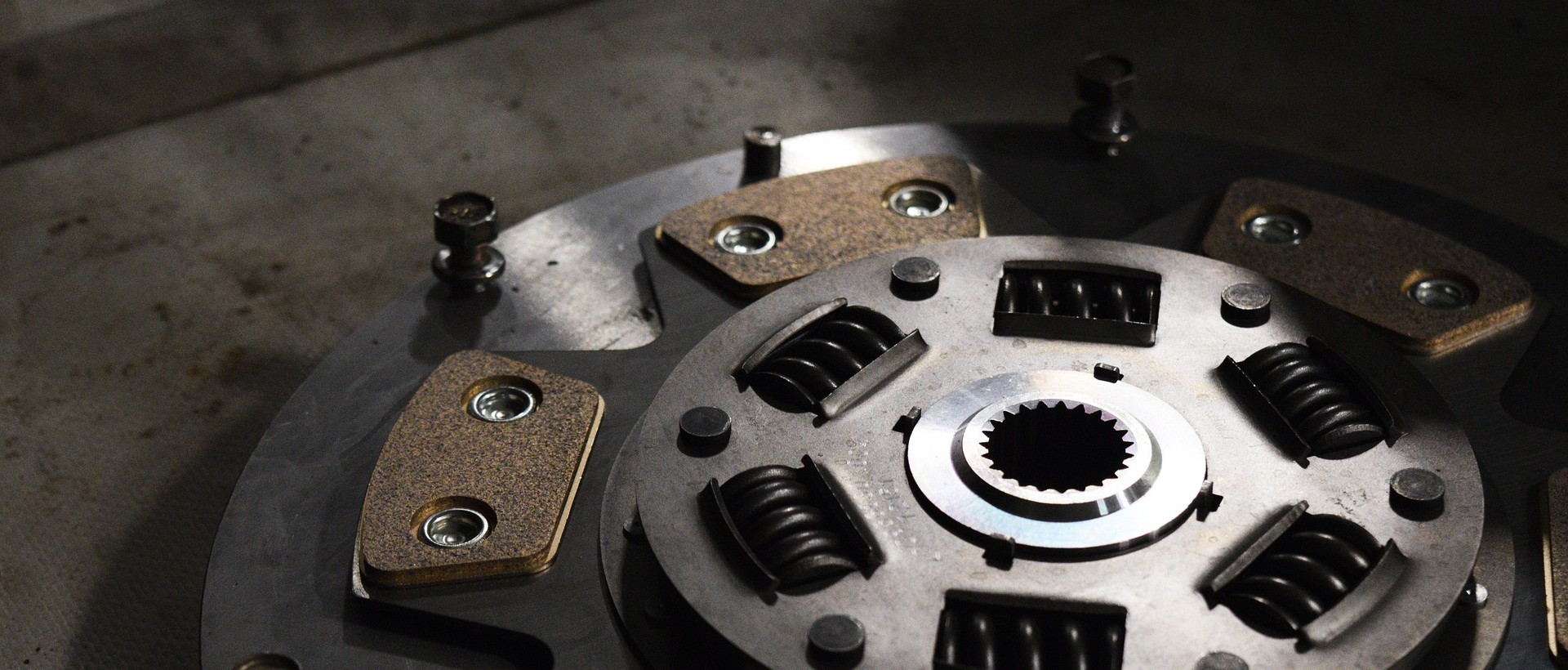

Electromagnetic brake is a commonly used adjusting element in mechanical transmission system, which is widely used in all kinds of lifting, conveying, metallurgy, mining and other mechanical equipment. However, the electromagnetic brake is prone to failure during long-term use. This article will be from how to judge the quality of electromagnetic brake and troubleshooting electromagnetic brake fault two aspects of the specific introduction.

1. Judging the quality of electromagnetic brake

The normal operation of the electromagnetic brake is related to its unique structure. When a magnetic field is generated in the power-on coil, the iron core will separate the brake friction plate from the stressed friction plate through axial displacement, so that the mechanical device can move freely. On the contrary, the electromagnetic force is not applicable to make the friction plate subject to pressure and friction, so that the mechanical device Stop moving. Therefore, the quality of the electromagnetic brake can be judged by the following methods:

① Inspection surface: check whether the appearance of the electromagnet is damaged or oxidized, and whether the bolts are loose.

② measuring coil resistance: usually the fault caused by poor contact of the center connection point can be eliminated by measuring the coil resistance. Most engineers rely on multimeters or ohmmeters to measure the resistance of wire windings, especially in the absence of nominal resistance values.

③ Full load pull-up test: test the load absorbed by the electromagnet. If it can be pulled up at full load, the electromagnet is working normally. It is also necessary to consider factors such as the stability of the load movement and the length of the stop time.

2. Failure analysis of electromagnetic brake

There are many types and causes of electromagnetic brake failure, but mainly include the following:

① Line problems: low power supply voltage, poor line contact, etc. will cause the electromagnetic brake to fail to work properly.

② core problems: core aging, deformation and other issues will affect the attraction of the electromagnet.

③Friction lining problem: For brakes that have been used for a long time, severe wear or loosening of the brake friction lining will affect normal operation.

When troubleshooting, it is necessary to locate and then detect. The specific operation can include the following steps:

① Check the line;

② Check the connection of iron core;

③ Verify the wear of the friction plate;

④ Check whether there is a fault in the mechanical part (such as transmission belt, bearing, etc.);

⑤ Final observation found the cause of the problem.

Hot News