News

news center

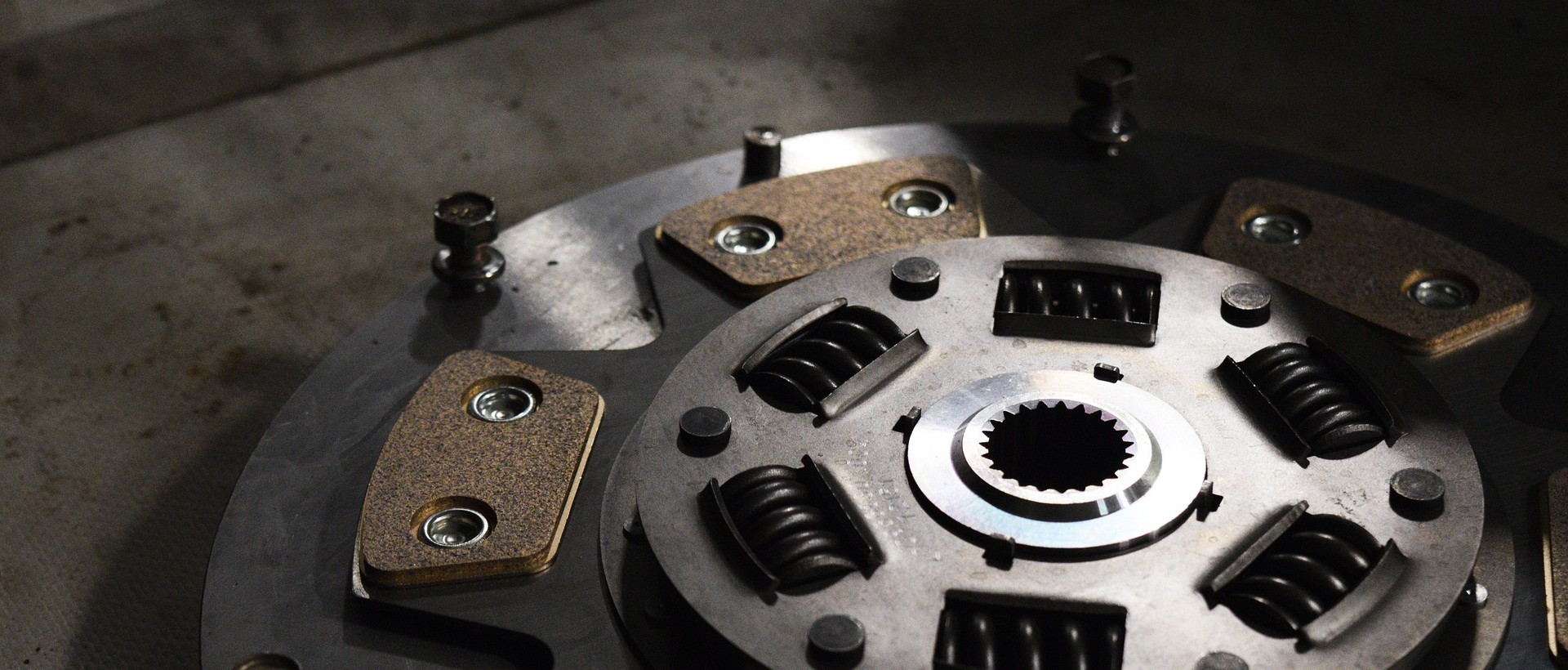

Electromagnetic brake maintenance and maintenance explained in detail

Release time:

2023-08-26

The electromagnetic clutch brake combination is referred to as the electromagnetic clutch brake combination, and has the following advantages:

1. The structure is simple and compact, the operation is simple, and the accurate combination can be guaranteed in a very short time. Moreover, the connection is reliable, the brake is flexible, and the automatic control and remote operation of the working mechanism can be realized.

2. An axially movable device composed of spring seats, pins, springs and friction plates, and replaces the spline sleeve in the currently widely used electromagnetic clutch to perform axial sliding, making the processing relatively simple and the installation and maintenance Also easy. The spring seat is made of aluminum alloy, which reduces the influence of remanence on the clutch effect. When designing the combination of electromagnetic clutch and brake, it is only necessary to check and calculate the shear and bending stress of the pin.

3. Due to the use of the armature fixed on the input shaft, the electromagnetic coil can be fixed on the end cover, which overcomes the shortcomings of ordinary electromagnetic clutches that need to set a wiring slip ring on the outer circumference of the rotating coil, and greatly reduces wear. Ensure reliable and timely power supply to the coil. The control power is small and the service life is long.

In order to ensure the uninterrupted operation of the electromagnetic brake, it must be maintained and maintained frequently.

Lubricant is often added to the movable part of the electromagnetic brake.

2. Always check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the housing, the bolts of the yoke, the bolts of the electromagnet coil and the terminal bolts.

3. If the worn braking surface is replaced, the minimum clearance between the braking surface and the turntable should be properly adjusted.

4. Regularly check the mechanical wear of the movable parts, and remove the dust, flower hair and dirt on the surface of the electromagnet parts.

5, regularly check the length of the armature stroke. This is because, during operation of the brake, the stroke length of the armature increases due to wear of the cross-sectional surface. When the armature stroke length does not reach the normal value, it must be adjusted to restore the minimum gap between the braking surface and the turntable. If the armature stroke length is increased above the normal value, the suction force may be greatly reduced.

Hot News